Process Delivery Orders in three Steps (Pick + Pack + Ship)¶

When an order goes to the shipping department for final delivery, Odoo is set up by default to utilize a one-step operation: once all goods are available, they are able to be shipped in a single delivery order. However, that process may not reflect reality and your company could require more steps before shipping.

With the delivery in 3 steps (Pick + Pack + Ship), the items will be picked to be transferred to a packing area. Then, they will be moved to an output location before being effectively shipped to the customers.

Activate Multi-Step Routes¶

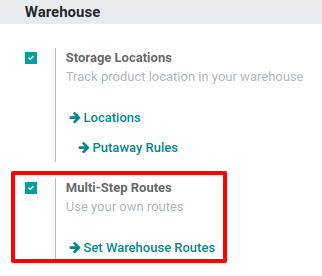

The first step is to allow using multi-step routes. Indeed, routes provide a mechanism to chain different actions together. In this case, we will chain the picking step to the shipping step.

To allow multi-step routes, go to and activate the option. Note that activating Multi-Step Routes will also activate Storage Locations.

Configure Warehouse for Delivery in 3 Steps¶

Once Multi-Step Routes has been activated, you can go to and enter the warehouse which will use delivery in 3 steps. You can then select the option Pack goods, send goods in output and then deliver (3 steps) for Outgoing Shipments.

Activating this option will lead to the creation of two new locations, Output and Packing Zone. If you want to rename it go to , Select the one you want to rename and update its name.

Create a Sales Order¶

In the Sales application, you can create a quotation with some storable products to deliver. Once you confirm the quotation, three pickings will be created and automatically linked to your sale order.

If you click the button, you should now see three different pickings:

The first one with a reference PICK to designate the picking process,

The second one with the reference PACK that is the packing process,

The last one with a reference OUT to designate the shipping process.

Process the Picking, Packing, and Delivery¶

The picking operation is the first one to be processed and has a Ready status while the other ones are Waiting Another Operation. The Packing operation will become Ready as soon as the picking one is marked as done.

You can enter the picking operation from here, or access it through the inventory dashboard.

In case you have the product in stock, it has automatically been reserved and you can simply validate the picking document.

Once the picking has been validated, the packing order is ready to be processed. Thanks to the fact that the documents are chained, the products which have been previously picked are automatically reserved on the packing order which can be directly validated.

Once the packing has been validated, the delivery order is ready to be processed. Here again, it is directly ready to be validated in order to transfer the products to the customer location.