Inventory management¶

In the Odoo Inventory app, warehouses handle the broader organization and distribution of stock across different physical sites, while locations provide a more detailed breakdown within each warehouse for efficient item management.

This document serves as an introduction to the terminology and concepts necessary to master Inventory. For specific instructions and examples of how things work, refer to individual documentation pages.

Warehouses¶

Warehouses represent a physical place, with a physical address, where a company’s items are stored.

Configure routes in a warehouse to control how products move to customers, from vendors, within the warehouse, or between warehouses.

Locations¶

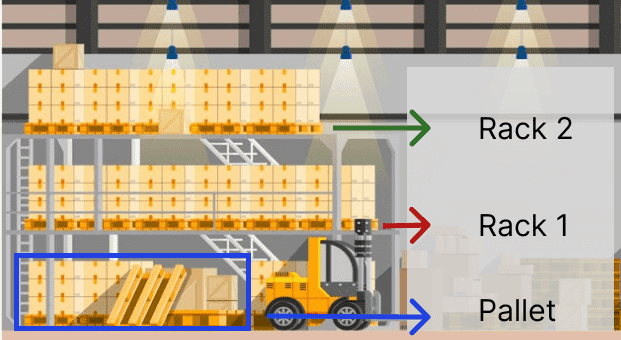

Locations refer to specific areas within a warehouse, such as shelves, floors, or aisles. These are sub-divisions within a warehouse, and are unique to that warehouse. Users can create and manage numerous locations within a single warehouse to organize inventory more precisely.

Location types¶

Location types in Odoo help categorize and manage where products are, and what actions need to be taken with them. By default, on the page, only internal locations are displayed.

To view the seven location types in Odoo, select any location, and in the Location Type field, there are:

Vendor Location: defines an area where products purchased from vendors originate. Items here are not in stock.

View: used to organize and structure the warehouse hierarchy. For example, the view location

WH(short for warehouse) groups all internal locations, such asStock, receiving docks, quality checkpoints, and packing areas to show they all belong to the same warehouse.Important

View locations should not contain products, but it is possible to move them there.

Internal Location: storage locations within the warehouse. Items stored in these locations are accounted for in inventory valuation.

Customer Location: where sold products are tracked; items here are no longer in stock.

Inventory Loss: counterpart location to consume missing items or create stock, accounting for discrepancies.

In Odoo, examples of inventory loss locations are Inventory Adjustment, used to account for discrepancies during an inventory count, and Scrap, which is where damaged goods are sent to account for inventory losses.

Example

Virtual Locations/Inventory Adjustmentis a location with the Inventory Loss type. The database shows65units inWH/Stock, but an inventory check reveals60. To correct the quantity, five units are moved fromWH/StocktoVirtual Locations/Inventory Adjustment.

Production: where raw materials are consumed, and manufactured products are created.

Transit Location: used for inter-company or inter-warehouse operations to track products shipped between different addresses, such as Physical Locations/Inter-warehouse transit.

Note

- In Odoo, location types are color-coded:

Red: internal locations

Blue: view locations

Black: external locations (including inventory loss, vendor, and customer locations).

View locations in Odoo¶

Odoo databases include pre-configured view locations to organize the hierarchy of locations. These provide helpful context, and distinguish between internal and external locations.

Physical locations serve as an umbrella for external locations, without changing a product’s inventory value. (Inventory valuation changes occur when products move from internal to external locations).

Example

When moving products in warehouses

WHandWH2, the items are not in either warehouse, but still belong to the company. While in transit, they are placed in theInter-warehouse transitlocation, a Transit Location type.This location is under the view location,

Physical Locations, indicating thatInter-warehouse transitis outside of a warehouse, but still part of the company. Doing so does not affect the inventory valuation of the products.

Partner locations group customer and vendor locations (external locations) together. Transfers to these locations affect inventory valuation.

Virtual locations are locations that do not exist physically, but it is where items that are not in inventory can be placed. These can be items that are no longer in inventory due to loss, or other factors.