In Odoo, a Warehouse is the actual building/place in which your items are stocked. You can setup multiple warehouses and create moves between warehouses.

A Location, is a specific space within your warehouse. It can be considered as a sublocation of your warehouse, as a shelf, a floor, an aisle, etc. Therefore, a location is part of one warehouse only and it is not possible to link one location to multiple warehouses. You can configure as many locations as you need under one warehouse.

Locations are understood by the Barcode App and you can print barcodes for them, or enter the barcode for them if you already have barcodes on your Racks - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/barcode/setup/software.html#set-locations-barcodes

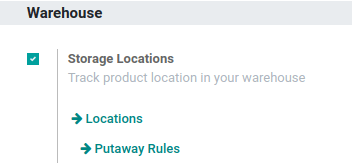

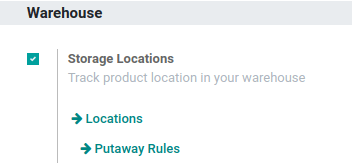

You can activate this feature from the Inventory App, Configuration --> Settings Menu:

Multi-step Routes support things like cross docking - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/routes/concepts/cross_dock.html

Storage Categories are useful if you have rules about where products are allowed to be stored, when they can be mixed, or need to know if a location is full BEFORE you try to put something there, and have an ALTERNATE location suggested instead. This is supported when your products can be created in advance (because you regularly receive them to REPLENISH quantities, perhaps because you are a third party fulfillment warehouse) - see https://www.cybrosys.com/blog/storage-categories-in-odoo-15

Packages are containers of products, like palettes or crates or totes, which also may (or may not) have separate barcodes. In addition to storing the location, you can store the package within the location. See https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/management/products/usage.html

A Consignment feature supports you assigning an Owner to each Receipt Transfer you receive - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/management/misc/owned_stock.html

Serial Numbers and Lots can optionally be recorded for high value products or those needing track and trace - see https://www.odoo.com/documentation/15.0/applications/sales/point_of_sale/shop/serial_numbers.html

Landed Costs can be added to the cost of the product if you charge per product fees or storage charges, etc. - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/management/reporting/integrating_landed_costs.html

We integrate with 3rd Party Shippers (UPS, FedEx, OnTrac, Deutsche Post, etc) to get labels and provide tracking information for shipments - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/shipping/setup/third_party_shipper.html

We support location based or task based inspections, with an audit trail of the inspection steps performed (and by whom) - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/inventory/management/delivery/inventory_flow.html and https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/manufacturing/management/quality_control.html

We have multi-company support (if you manage multiple LLC's or legal entities) - see https://www.odoo.com/documentation/15.0/developer/howtos/company.html

We have multi-currency support (if you work in multiple countries) see https://www.odoo.com/documentation/15.0/applications/finance/accounting/getting_started/main_concept.html

We have an Email Server (or can integrate with your email system), with all emails available from beneath the corresponding Receipt, Transfer, Return, Delivery, etc. See https://www.odoo.com/documentation/15.0/applications/general/email_communication/email_domain.html

We have an integrated Order Management (Purchase Orders and Sales Orders) system - see https://www.odoo.com/documentation/15.0/applications/inventory_and_mrp/purchase.html and https://www.odoo.com/documentation/15.0/applications/sales/sales.html

Our Customer Portal gives your Customers a view into the status of their shipments. See https://www.odoo.com/documentation/15.0/applications/sales/sales/advanced/portal.html

Our Invoicing App manages your billing - see https://www.odoo.com/documentation/15.0/applications/finance/accounting.html

@Licia Portu, If you use the Basic 'Inventory' and 'barcode' Module, then I'd say Yes, you will face such issues when dealing with storing and 3PL.

BUT.

With a little bit of customization and the help of a good partner, we were able to resolve most of our critical issues and migrate our operations onto odoo with 90% of our issues resolved, the remaining 10% to be solved during the go-live period.

Are such issues common for 3rd party logistics and storing?

Are such issues common for 3rd party logistics and storing?

/I need the same exact thing for an 3pl warehousing, did you find any solution let me know. Thanks