Removal strategies (FIFO, LIFO, FEFO)¶

For companies with warehouses, removal strategies determine which products are taken from the warehouse, and when. Removal strategies are typically defined for specific picking operations. This helps companies to select the best products, optimize the distance workers need to travel when picking items for orders, and account for quality control, such as moving products with expiration dates.

Usually, Removal Strategies are defined in picking operations to select the best products to optimize the distance for the worker, for quality control purposes, or to first move the products with the closest expiration date.

When a product needs to be moved, Odoo finds available products that can be assigned to the transfer. The way Odoo assigns these products depends on the Removal Strategy defined in either the Product Category or the Location dashboards.

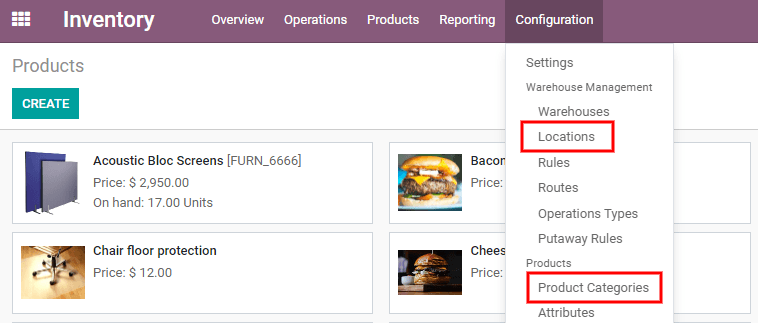

To change the Removal Strategy, go to or . Click on a Location or Product Category, and then click Edit. Change the product category Force Removal Strategy or the location Removal Strategy by clicking on the drop-down menu and selecting the desired removal strategy. After selecting the new removal strategy, click Save.

What happens inside the warehouse?¶

Most warehouses share the same important areas: receiving docks and sorting areas, storage locations, picking and packing areas, and shipping/loading docks. While all products entering or leaving the warehouse might go through each of these locations at some point, removal strategies can have an effect on which products are taken, from where, and when.

In this example below, vendor trucks unload pallets of goods at the receiving docks. Then, operators scan the products in the receiving area, with the reception date and expiration date. After that, products are stored in their respective storage locations.

Note

Not all products have expiration dates, but in this example, expiration dates apply.

In Odoo, receive products by navigating to the application, and in the kanban view, click on either the Receipts heading or # TO PROCESS button. On the Receipts dashboard, find and click on the individual receipt which will open the warehouse intake form. Click Edit, and then enter the received quantity in the Done column. To finish, Validate to receive the products and register them in the Odoo database.

Tip

Receiving products can also be done within the Odoo Barcode application. If using the Barcode app, scan the product(s), update the quantity, and finally, click Validate. After products are received in Odoo, the products can then be moved to their respective storage locations.

Continuing with the same example, below, imagine several sales orders are made for the products received earlier, that use expiration dates. In this example, the products weren’t received on the same day, and they don’t have the same expiration date. In this situation, logically, sending products with the closest expiration date is preferred, instead of products received first or last. Using the chosen removal strategy configured for those products (in this example, FEFO), Odoo generates a transfer for the products with the soonest expiration date to the picking area, then the packing area, and finally, to the shipping docks for delivery to the customer.

Note

To pick for delivery, the product’s lot/serial number can be found on the transfer form. To learn more about picking and shipping, refer to either the Two-step delivery or Three-step delivery documentation.

How each removal strategy works¶

Removal strategies determine which products are taken from the warehouse when orders are confirmed.

First In, First Out (FIFO)¶

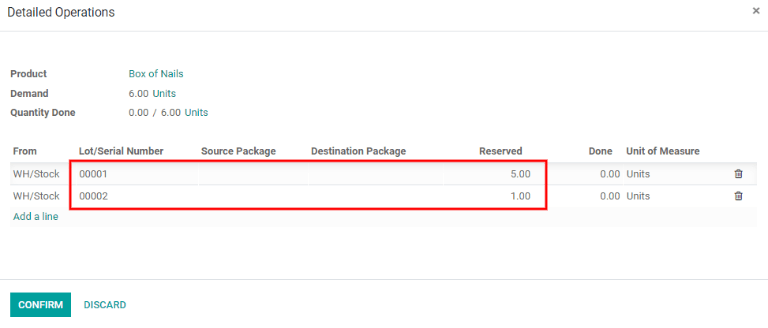

When using a First In, First Out (FIFO) strategy, demand for a product triggers a removal rule, which requests a transfer for the lot/serial number that entered the stock first (and therefore, has been in stock for the longest time).

For example, imagine there are three lots of nails in the warehouse, and have the corresponding lot

numbers: 00001, 00002, 00003. Each lot has five boxes of nails in it.

Lot 00001 entered the stock on May 23, lot 00002 on May 25, and lot 00003 on June 1. A

customer orders six boxes on June 11.

Using the FIFO removal strategy, a transfer request will pick the five

boxes from lot 00001 first, and then from the boxes in lot 00002, since lot 00001 entered the

stock first. The box from lot 00002 is taken next because it has the oldest receipt date after lot

00001.

Last In, First Out (LIFO)¶

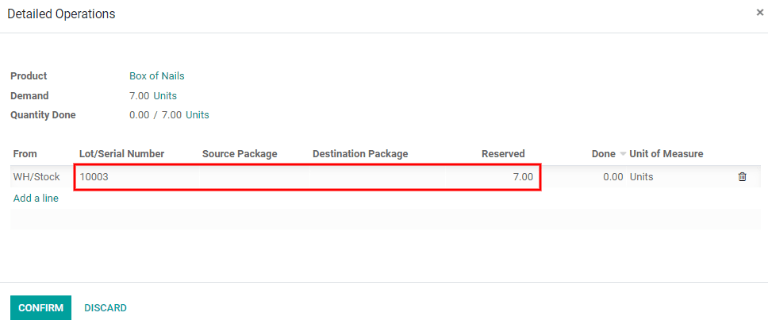

Similar to the FIFO method, the Last In, First Out (LIFO) removal strategy moves products based on the date they entered a warehouse’s stock. Instead of removing the oldest stock on-hand, however, it targets the newest stock on-hand for removal.

Every time an order for products with the LIFO method is placed, a transfer is created for the lot/serial number that has most recently entered the stock (the last lot/serial number that entered the warehouse’s inventory).

Warning

In many countries, the LIFO removal strategy in banned, since it can potentially result in old, expired, or obsolete products being delivered to customers.

For example, imagine there are three lots of boxes of screws in the warehouse, and have the

corresponding lot numbers: 10001, 10002, and 10003, each with 10 boxes of screws per lot.

Lot 10001 entered the stock on June 1, lot 10002 on June 3, and lot 10003 on June 6. A

customer orders seven boxes on June 8.

Using the LIFO removal strategy, a transfer is requested for seven

boxes of screws from lot 10003 because that lot is the last one to have entered the stock.

First Expired, First Out (FEFO)¶

While the FIFO and LIFO methods target products for removal based on date of entry into the warehouse, the First Expired, First Out (FEFO) method targets products for removal based on their assigned expiration dates.

Using the FEFO removal strategy, every sales order that includes products with this removal strategy assigned ensures that transfers are requested for products with the expiration date soonest to the order date.

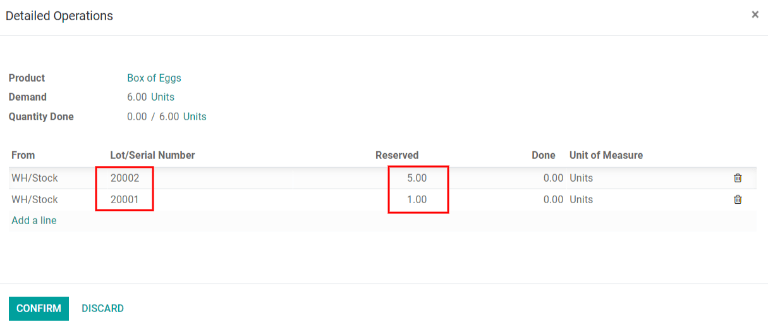

As an example, imagine there are three lots of six-egg boxes. Those three lots have the following

lot numbers: 20001, 20002, and 20003, each with five boxes in it.

Lot 20001 entered the stock on July 1 and expires on July 15, lot 20002 entered on July 2 and

expires on July 14, and lot 20003 entered on July 3 and expires on July 21. A customer orders six

boxes on July 5.

Using the FEFO method, a transfer is requested for the five boxes

from lot 20002 and one from lot 20001. All the boxes in lot 20002 are transferred because they

have the earliest expiration date. The transfer also requests one box from lot 20001 because it

has the next closest expiration date after lot 20002.

Using removal strategies¶

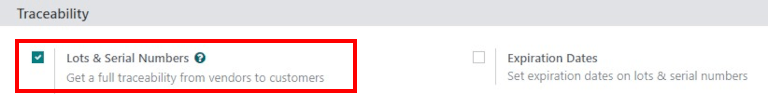

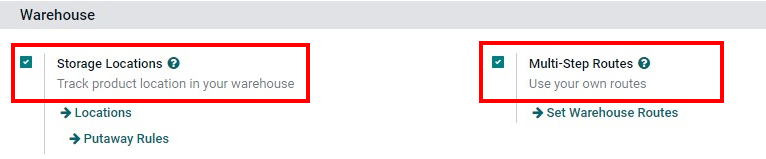

To differentiate some units of products from others, the units need to be tracked, either by Lot or by Serial Number. To do so, go to . Then, activate the Storage Locations, Multi-Step Routes, and Lots & Serial Numbers settings. Click Save to save changes.

Note

To use the FEFO removal strategy, the Expiration Dates setting needs to be activated as well. To enable this, go to , scroll down to the Traceability section, and click the checkbox next to Expiration Dates. Remember to click Save to save all changes.

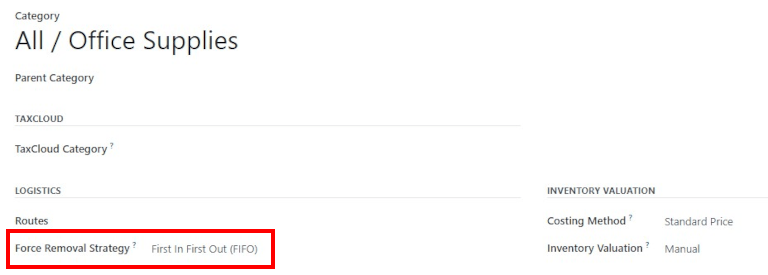

Now, specific removal strategies can be defined on product categories. To do this, go to , and choose a product category to define the removal strategy on. In the Force Removal Strategy field, choose a removal strategy.

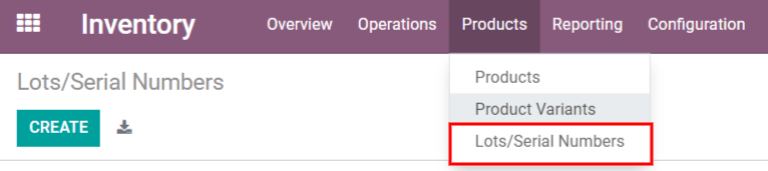

To view all products with lots/serial numbers assigned to them, navigate to . This reveals a page with drop-down menus of all products assigned lots or serial numbers, filtered by product by default. To change the category these products are filtered by, click Product (in the search bar, in the top right of the page) to remove the default filter, and select a new filter if desired.

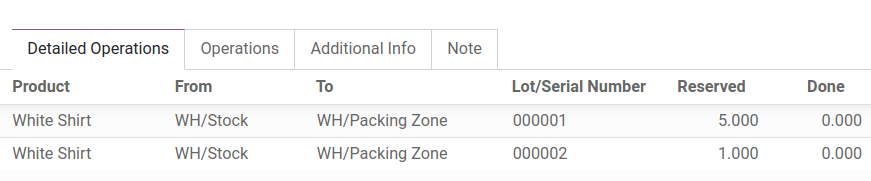

To view the serial numbers being selected for a sales order, go to the Sales app and select the sales order in question. In the sales order, click the Delivery smart button in the top right. In the Operations tab, click the ⦙≣ (Detailed Operations) icon in the far right for the product in question. The Detailed Operations window appears, and displays the lot or serial numbers selected for that specific product for the delivery order.

FIFO (First In, First Out)¶

The FIFO removal strategy implies that products which enter a warehouse’s stock first are removed first. Companies should use this method if they are selling products with short demand cycles, such as clothes, to ensure they are not stuck with outdated styles in stock.

In this example, there are three lots of white shirts. The shirts are from the All/Clothes category, where FIFO is set as the removal strategy. In the Inventory Valuation Report, the three different receipts are listed with the amounts.

Lot 000001 contains five shirts, lot 000002 contains three shirts, and lot 000003 contains two

shirts.

To see the removal strategy in action, go to the and click

Create to create a sales order. Next, select a Customer from the drop-down

menu. Then click Add a product in the Order Lines tab. Select a product (for

this example, the White Shirt) from the drop-down menu, or type in the name of the

product in the field. Enter a quantity (for this example, 6.00) in the Quantity field,

then click Save, then click Confirm.

Once the sales order is confirmed, the delivery order will be created and linked to the picking, and

the oldest lot numbers will be reserved thanks to the FIFO strategy.

All five shirts from lot 000001 and one shirt from lot 000002 will be selected to be sent to the

customer.

LIFO (Last In, First Out)¶

The LIFO removal strategy works in the opposite manner from the FIFO strategy. With this method, the products that are received last are moved out first. This method is mostly used for products without a shelf life, and no time-sensitive factors, such as expiration dates.

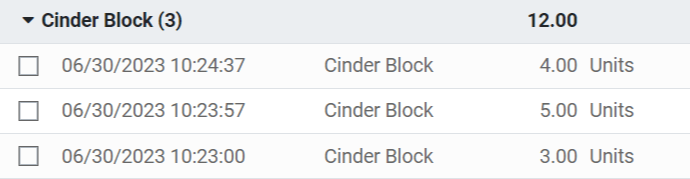

In this example, there are three lots of cinder blocks. The blocks are from the All/Building Materials category, where FIFO is set as the removal strategy. In the Inventory Valuation Report, the three different receipts are listed with the amounts.

Lot 000020 contains three cinder blocks, lot 000030 contains five cinder blocks, and lot

0000400 contains four cinder blocks.

To see how the LIFO strategy works, first navigate to , and select a product category (for this example, the All/Building Materials category) to edit. This reveals a product category form.

Once on the product category form, under the Logistics section, change the Force Removal Strategy to Last In First Out (LIFO).

To see the removal strategy in action, go to the and click

Create to create a sales order. Next, select a Customer from the drop-down

menu. Then click Add a product in the Order Lines tab. Select a product (for

this example, the Cinder Block) from the drop-down menu, or type in the name of the

product in the field. Enter a quantity (for this example, 5.00) in the Quantity field,

then click Save, then click Confirm.

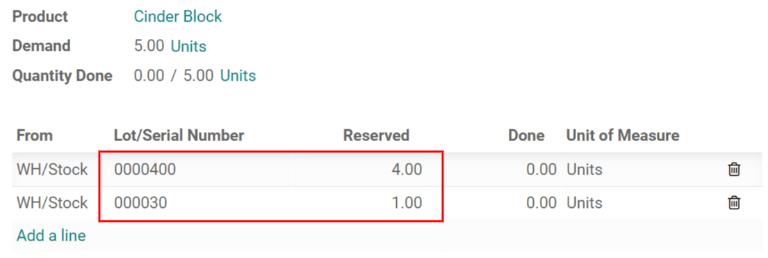

Once the sales order is confirmed, the delivery order will be created and linked to the picking, and

the newest lot numbers will be reserved thanks to the LIFO strategy.

All four cinder blocks from lot 0000400 and one cinder block from lot 000030 will be selected to

be sent to the customer.

FEFO (First Expired, First Out)¶

The FEFO removal strategy differs from the FIFO and LIFO strategies, because it targets products for removal based on expiration dates instead of their warehouse receipt dates. With this method, the products that are going to expire first are moved out first. This method is used for perishable products, such as medicine, food, and beauty products.

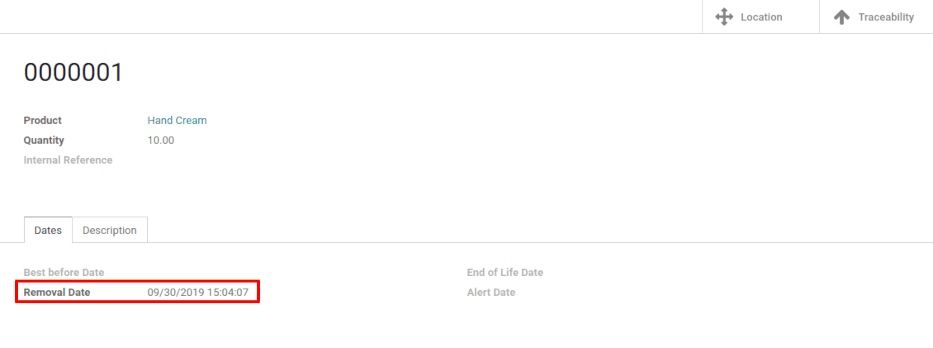

Lots are picked based on their removal date from earliest to latest. Removal dates indicate how many days before the expiration date the product needs to be removed from stock. The removal date is set on the product form. Lots without a removal date defined are picked after lots with removal dates.

Warning

If products are not removed from stock when they should be, lots that are past the expiration date may still be picked for delivery orders!

Note

For more information about expiration dates, reference the Expiration dates document.

First, go to and ensure Expiration Dates is enabled. Once the Expiration Dates setting is enabled, it’s possible to define different expiration dates for individual serialized products, as well as for lot numbers containing many products.

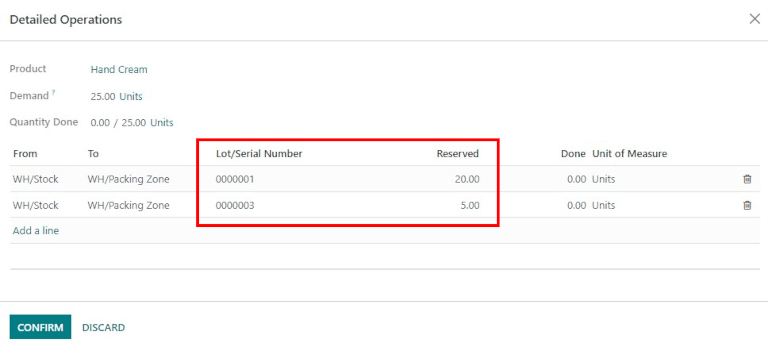

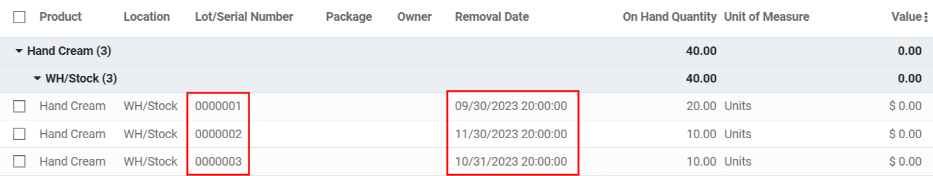

In this example, there are three lots of hand cream. The creams are from the All/Health & Beauty category, where FEFO is set as the removal strategy. In the Inventory Valuation Report, the three different receipts are listed with the amounts.

Lot 0000001 contains twenty tubes of hand cream, expiring on Sept 30, lot 0000002 contains ten

tubes of hand cream, expiring on November 30, and lot 0000003 contains ten tubes of hand cream,

expiring on October 31.

Expiration dates can be entered when validating the received products, or set on products by going to . Click Create, enter the serial number, and select the product from the drop-down menu. Next, select the expiration date in the Dates tab. Finally, click Save.

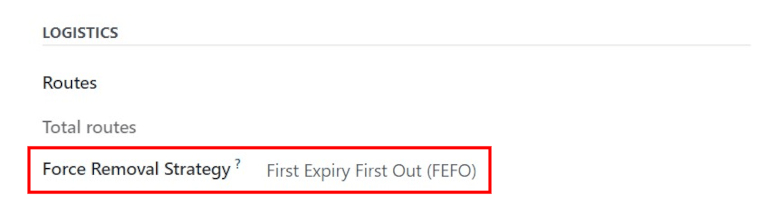

To see how the FEFO strategy works, first navigate to , and select a product category (in this example, the All/Health & Beauty category) to edit. This reveals a product category form.

Once on the product category form, under the Logistics section, change the Force Removal Strategy to FEFO.

Next, go to the and click Create to create a sales order.

Next, select a Customer from the drop-down menu. Then click Add a product in

the Order Lines tab. Select a product (for this example, the Hand Cream)

from the drop-down menu, or type in the name of the product in the field. Enter a quantity (in this

example, 25.00) in the Quantity field, then click Save, then click

Confirm.

Once the sales order is confirmed, the delivery order will be created and linked to the picking, and

the lot numbers expiring first will be reserved thanks to the FEFO strategy. All twenty tubes of hand cream from lot 0000001 and five from lot 0000003 will

be selected to be sent to the customer, detailed in the Detailed Operations tab in the

sales order.